or most of his life, Israeli-born Yehoram Uziel, 48, regarded

industry's traditional methods for making metal parts in the

same scornful way that Gutenberg, five centuries ago, must have

viewed the hand copying of books. The parts have to be machined

in a time-consuming process that wastes metal or cast in molds

that often take skilled craftsmen months to make. Uziel's dream

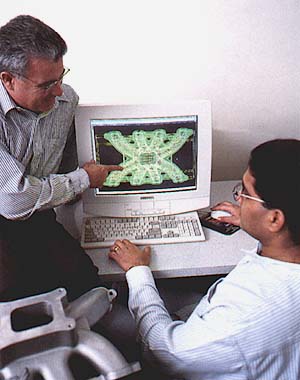

was to produce parts directly from the computer-aided design

(CAD) images that have become industry's blueprints. "I wanted

to be another Gutenberg," he says.

He is close to realizing his dream. CAD drawings are Uziel's

equivalent of Gutenberg's movable type. These are fed into a

special machine--a counterpart of the printing press--that

quickly converts the images into three-dimensional ceramic

objects. The machine can create industrial prototypes or end

products, as well as ceramic molds used in a metal foundry. At

Soligen Technologies, the small publicly held company that Uziel

started in the Los Angeles suburb of Northridge, a visitor can

watch the 3-D printer building up a ceramic mold in mere hours.

Successive layers of sand deposited by rollers are solidified as

100 printer heads, following the CAD design, selectively squirt

drops of a gluelike substance. When finished, the mold is taken

to a Soligen-owned foundry, and hot metal is poured in to make

the part.

Industry has taken notice, and Uziel's 60-employee company has

been running on a three-shift, seven-day schedule. Revenues

jumped 30%, to $5.5 million, in the company's latest fiscal

year. Many of the parts Soligen casts in its foundry are metal

prototypes suitable for rigorous developmental testing by such

customers as GM, Caterpillar, and many others. But in the past

year Soligen has achieved what Uziel considers the final step in

Gutenberg terms: turning computer images into metal molds

durable enough to mass-produce aluminum, magnesium, or zinc parts.

Uziel's last name in Hebrew combines "strength" (Uzi) and "God"

(el). He has needed both on the bumpy road he has traveled,

which included combat duty in the Arab-Israeli wars. An

outstanding student at Technion, Israel's counterpart of MIT, he

was the only undergraduate engineer picked to work with his

Ph.D. teachers in a defense lab. With his boss at the lab, Uziel

co-founded Optrotech Ltd., which became the world's leading

maker of instruments using a laser to inspect printed

circuitboards.

One day it occurred to him that a laser could trace outlines on

a light-sensitive film emulsion, causing the emulsion to

solidify. If stacked, the outlines could form an object. Uziel

became convinced he could build a 3-D printer capable of making

plastic prototypes for industry. But a California engineer,

Charles W. Hull, beat him by 45 days in filing a European

patent. Uziel served for a time as a VP of Hull's company, 3-D

Systems, but still dreamed of mass-producing metal parts. The

question was how.

The answer came in 1991, when he read about a 3-D printing process being

developed at MIT, in which layers of powdered materials were solidified

with glue squirted from an inkjet printer. Uziel persuaded the developers

of the MIT process to give him an exclusive license to apply their idea

to metal casting. With a few colleagues, he worked around the clock in

his California garage to build big 3-D printers. He could find no venture

capitalists to back him on acceptable terms; one wanted 60% of his company

for $2 million. The persistent Uziel was able to raise $1.2 million from

Pratt & Whitney, Johnson & Johnson, and the Sandia national laboratory

in return for the right to use his machine experimentally. He also raised

$4.2 million through a stock offering and got Soligen listed on the American

Stock Exchange.

The answer came in 1991, when he read about a 3-D printing process being

developed at MIT, in which layers of powdered materials were solidified

with glue squirted from an inkjet printer. Uziel persuaded the developers

of the MIT process to give him an exclusive license to apply their idea

to metal casting. With a few colleagues, he worked around the clock in

his California garage to build big 3-D printers. He could find no venture

capitalists to back him on acceptable terms; one wanted 60% of his company

for $2 million. The persistent Uziel was able to raise $1.2 million from

Pratt & Whitney, Johnson & Johnson, and the Sandia national laboratory

in return for the right to use his machine experimentally. He also raised

$4.2 million through a stock offering and got Soligen listed on the American

Stock Exchange.

Soligen's process, called direct shell production casting, or

DSPC, has advantages over conventional casting. While all

casting makes possible parts with complex geometries, DSPC

eliminates a number of steps in conventional moldmaking and can

create more precise shapes with intricate internal cavities.

Ceramic molds have one big drawback, however. They can be used

only once since they are made in one piece and must be broken to

get at metal parts. Soligen's ceramic molds still represent an

advance, because the company can make lots of them quickly, as

needed.

Soligen has also begun using DSPC to make long-lived metal

molds, which ordinarily must be machined. Here's how: Instead of

making a ceramic mold in his 3-D printer, Soligen uses reverse

CAD imaging to create ceramic molds into which steel can be

poured to make two halves of a permanent mold. The resulting

"hard tool" can make thousands of parts from any metal with a

lower melting point than the steel mold. Soligen recently

delivered permanent molds to Chicago Pneumatics, a maker of

hand-held tools, which is evaluating them. Says Uziel: "We

expect the life expectancy of these permanent molds to be as

good as or maybe better than that of conventional tools."

Uziel's long-term strategy is to launch a network of franchised

rapid-response facilities where CAD files can be transformed on

the spot into finished parts or tools. The service centers, to

be called Parts Now, will be located around the world and will

have DSPC machines as well as casting and machining equipment.

Last year Uziel took the first step by granting a consortium of

French companies a license to operate a DSPC machine in an

experimental center in Le Mans. Gutenberg would have approved.